Technology Transfer

Colloidal Gold diagnostic platform-based products undergo eight production procedures from raw material to finished product. These procedures are: Formulation, Spraying, Antibody Scribbling, Membrane Pasting, Sheet Cutting, Shell Pressing, Foil Bag Sealing, and Labeling. Major human resources required are well educated biomedical chemical talents, management talents and skilled line workers.

The key production technologies are well-documented and can be effectively transferred to locally recruited employees through comprehensive training programs. With adequate training and support, local workers can quickly acquire the necessary skills to operate and maintain the production line efficiently. This will not only create job opportunities but also foster the development of a skilled workforce in Nigeria’s IVD industry.

The key production technologies are well-documented and can be effectively transferred to locally recruited employees through comprehensive training programs. With adequate training and support, local workers can quickly acquire the necessary skills to operate and maintain the production line efficiently. This will not only create job opportunities but also foster the development of a skilled workforce in Nigeria’s IVD industry.

EMPOWERING INNOVATION

Research and Development

Project Black Shield’s commitment to Research and Development (R&D) will foster cutting-edge innovations in healthcare technology and manufacturing processes. Key initiatives include:

Research and Development

Project Black Shield’s commitment to Research and Development (R&D) will foster cutting-edge innovations in healthcare technology and manufacturing processes. Key initiatives include:

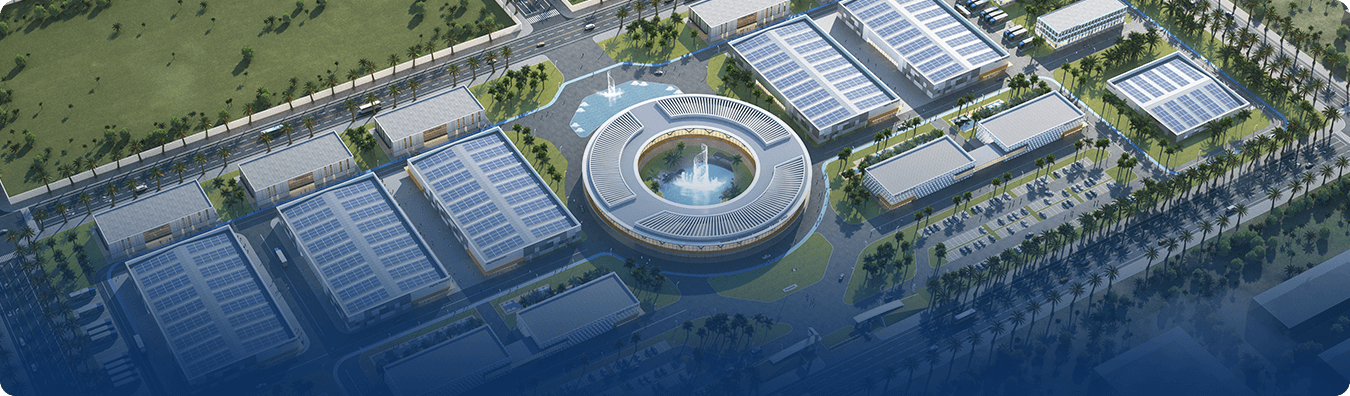

- Advanced R&D Facilities : Establishing state-of-the-art laboratories and research centers focused on developing new diagnostic tests, vaccines, and biologics tailored to the specific health needs of Nigeria and the broader African continent.

- Collaborative Research Projects : Partnering with local and international research institutions to undertake collaborative projects that drive innovation and improve healthcare outcomes.

- Intellectual Property Development : Encouraging the creation and protection of intellectual property (IP) generated through R&D activities to ensure the sustainability and competitiveness of Nigeria’s healthcare industry.

Technology Transfer

Technology transfer is a core component of Project Black Shield, aimed at building local capacity and self-reliance in the production of critical healthcare products. Key activities include:

Technology Transfer

Technology transfer is a core component of Project Black Shield, aimed at building local capacity and self-reliance in the production of critical healthcare products. Key activities include:

- Partnerships with Global Leaders : Collaborating with leading global manufacturers and technology providers to transfer knowledge, skills, and technology for the local production of IVDs, vaccines, and biologics.

- Local Expertise Development : Training local scientists, engineers, and technicians in advanced manufacturing techniques and quality control processes to ensure the highest standards of production.

- Sustainable Production : Implementing best practices in sustainable manufacturing to minimize environmental impact and ensure the long-term viability of local production.

CAPACITY BUILDING

Building local capacity is essential for the success and sustainability of Project Black Shield. Key initiatives include:

Building local capacity is essential for the success and sustainability of Project Black Shield. Key initiatives include:

- Workforce Development : Establishing the Africa Bio Training Center (ABC) to provide specialized training programs for local talent in IVD technologies, vaccine production, and biologics manufacturing. This will create a skilled workforce capable of sustaining and advancing the healthcare sector.

- University-Industry Collaboration : Creating University-Industry joint Innovation Centers (UIIC) to foster collaborative research, support talent development, and drive innovation in healthcare technology.

- Incubation and Support for Startups: Launching the Africa BioMed Center (ABMC) to incubate and support emerging Bio, MedTech, and Digital-Health startups. This will stimulate innovation and entrepreneurship, contributing to the growth of the local healthcare industry.